PRODUCTS

OEM & ODM Pwm Yas Qhov Txhaj Molding Cov Khoom Muag Moulding Service

Khoom Taw Qhia

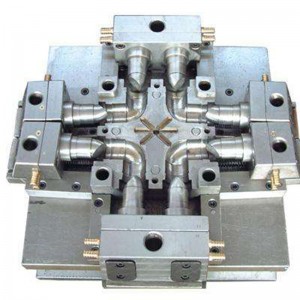

Yas txhaj tshuaj molding yog txheej txheem tsim khoom uas koom nrog kev tsim cov khoom yas los ntawm kev siv cov pwm tsim tshwj xeeb.Cov pwm feem ntau yog ua los ntawm cov hlau thiab tsim los rau cov duab thiab qhov loj ntawm qhov xav tau, nrog cov kab noj hniav thiab cov kab rau kev txhaj tshuaj ntawm cov khoom yas.Cov txheej txheem yas txhaj tshuaj molding pib nrog kev npaj cov pwm, uas yuav tsum tau tshwj xeeb machining lossis fabrication.Cov pwm yog ces clamped nyob rau hauv qhov chaw nyob rau hauv lub txhaj tshuaj molding tshuab, uas muaj ib tug hopper rau cov khoom yas, ib tug rhuab chim chim uas melts cov khoom, thiab ib tug plunger los yog ntsia hlau uas yuam cov molten yas rau hauv pwm.Thaum cov pwm puv lawm, nws raug tso cai kom txias thiab khov, feem ntau siv ob peb feeb lossis feeb, nyob ntawm qhov loj thiab qhov nyuaj ntawm qhov.Cov pwm yog tom qab ntawd qhib, thiab qhov ua tiav yog ejected los ntawm pwm kab noj hniav.Cov txheej txheem no tuaj yeem rov ua dua los tsim ntau qhov chaw zoo ib yam, nrog rau kev txhaj tshuaj molding tshuab txiav cycling los ntawm cov txheej txheem.Yas txhaj tshuaj molding muaj ntau qhov zoo dua lwm cov txheej txheem tsim khoom, suav nrog lub peev xwm los tsim cov duab puab, kev ua haujlwm siab thiab rov ua dua, thiab cov nqi qis zog.Tsis tas li ntawd, kev siv cov ntaub ntawv yas tso cai rau ntau yam ntawm lub cev thiab tshuaj lom neeg lub zog, ua rau cov khoom tsim nrog cov kev xav tau tshwj xeeb rau lub zog, hloov tau yooj yim, pob tshab, thiab tsis kam tiv tshav kub, tshuaj lom neeg lossis lwm yam ib puag ncig.Zuag qhia tag nrho, yas txhaj tshuaj molding yog ib tug ntau yam thiab efficiency manufacturing txheej txheem uas yog dav siv nyob rau hauv ntau industries, los ntawm automotive thiab aerospace mus rau cov khoom kho mob thiab cov neeg siv khoom.

FAQ

Yas txhaj tshuaj molding yog txheej txheem tsim khoom uas cov khoom siv yas molten yog txhaj rau hauv lub pwm kab noj hniav kom tsim tau ib qho qauv lossis tsim.Nws yog siv los tsim ntau yam khoom yas, los ntawm cov khoom me me mus rau qhov chaw loj

Ntau yam khoom siv yas tuaj yeem siv rau hauv kev txhaj tshuaj molding, nrog rau cov thermoplastics, thermosetting plastics, thiab elastomers.Feem ntau siv cov thermoplastics xws li ABS, polycarbonate, nylon, thiab polypropylene.

Yas txhaj tshuaj molding muaj ntau yam txiaj ntsig, suav nrog cov nqi tsim khoom siab, zoo ib yam thiab rov ua dua ib feem ntau lawm, tsim kev yooj yim, thiab tus nqi-zoo rau kev ntim ntau lawm.

Cov yas txhaj tshuaj pwm yog tsim los ntawm kev siv computer-aided design (CAD) software los tsim cov qauv 3D kom ntxaws ntawm cov khoom.Cov qauv no yog tom qab siv los tsim cov pwm siv cov txheej txheem machining siab heev xws li CNC machining lossis qhov hluav taws xob yaig.

Yuav kom tswj tau qhov zoo ntawm cov yas txhaj tshuaj molding, nws yog ib qho tseem ceeb uas yuav tsum tau siv cov ntaub ntawv zoo, tswj thiab tshuaj xyuas cov tshuab txhaj tshuaj molding thiab cov cuab yeej tsis tu ncua, thiab ua cov kev tswj xyuas zoo ntawm txhua qhov kev tsim khoom kom ntseeg tau tias kev ua tau zoo thiab cov khoom zoo.

Feem ntau cov teeb meem hauv kev txhaj tshuaj yas molding muaj xws li warpage, dab dej cim, flashing, thiab deg imperfections.Txhawm rau kom tsis txhob muaj cov teeb meem no, nws yog ib qho tseem ceeb uas yuav tsum tau kho qhov kev txhaj tshuaj nrawm thiab siab, tswj cov cua txias, thiab xaiv cov khoom tsim nyog thiab pwm tsim.

Cov khoom qeb

-

E-mail

-

WhatsApp

-

Xov tooj

Tel

-

Linkedin

-

Wecaht

Wecaht